PRODUCTS / PARTS / TEKNIKA CRANKS | TEKNIKA PEDALS | TEKNIKA STEMS

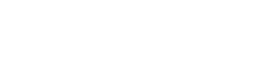

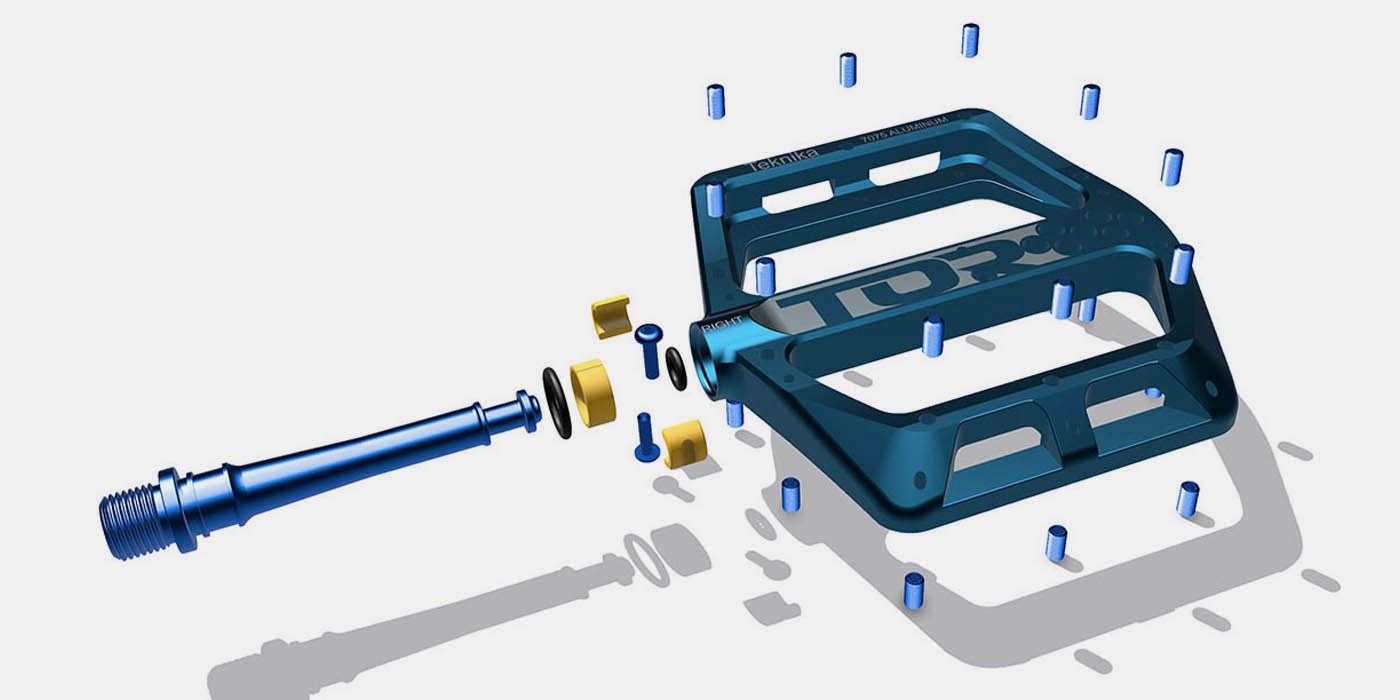

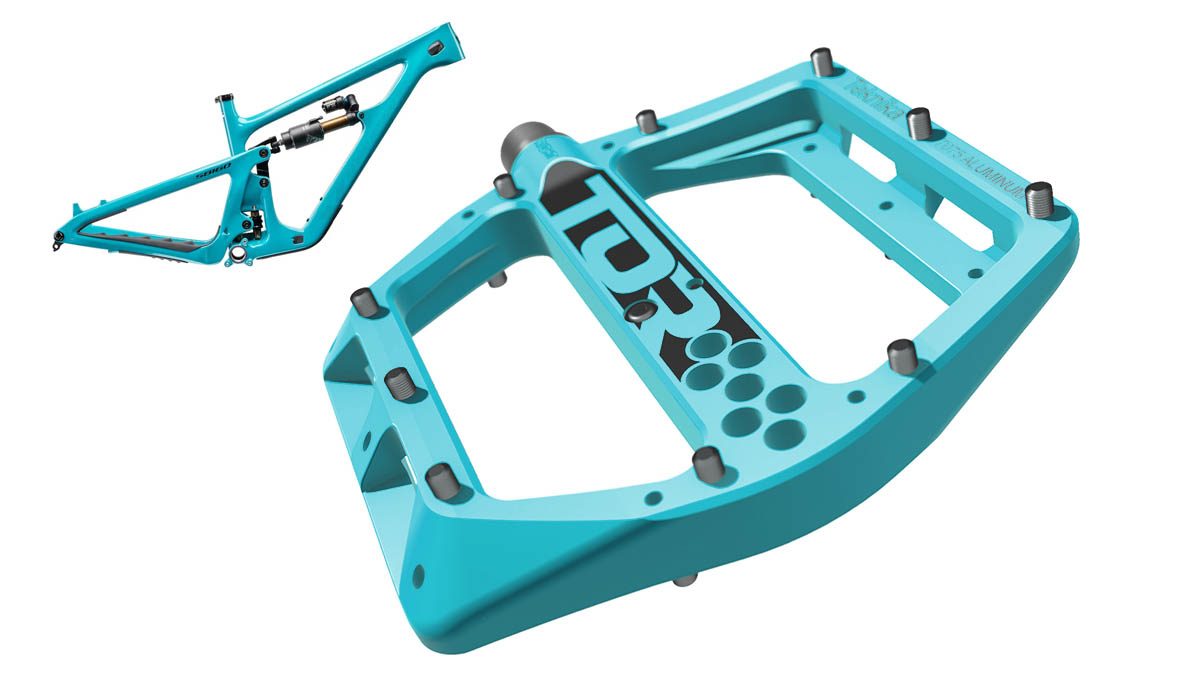

TEKNIKA PEDALS

7075 Aluminum | Titanium | Cerakote

$330.00 USD

PRE-ORDER NOW FOR AUGUST PRODUCTION RUN

$80 DEPOSIT

CHOOSE YOUR CUSTOM COLORS – We have 18 stock Cerakote colors or you can select PICK MY OWN COLOR and we will contact you to match any color you want. – SEE COLOR CHART

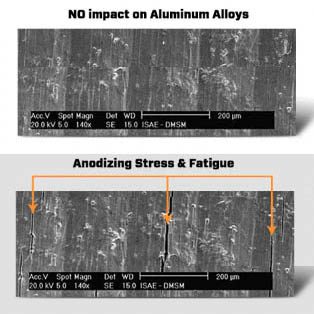

Cerakote Ceramic Coating

Cerakote is a high-end ceramic finish that was developed for the extremely high demands firearms industry. It offers industry leading durability, hardness, and scratch resistance, as well as chemical resistance, that will protect the overall finish of your bike. Cerakote is not prone to the chipping and blistering commonly found in existing paint finishes, and is not affected by chemicals such as road oil and tar, chain lube and brake fluid.

Cerakote Vs. Anodizing

Stock black/silver/gold

Custom color options

Matte or gloss

Go nuts!

T-30 Torx fittings

Custom Color Chart

These are our custom color options. If you want something that we don’t have here, just let us know and we can quote you. If you want some inspiration, check out our friends at Daylight – www.daylightcycles.com/finishes/

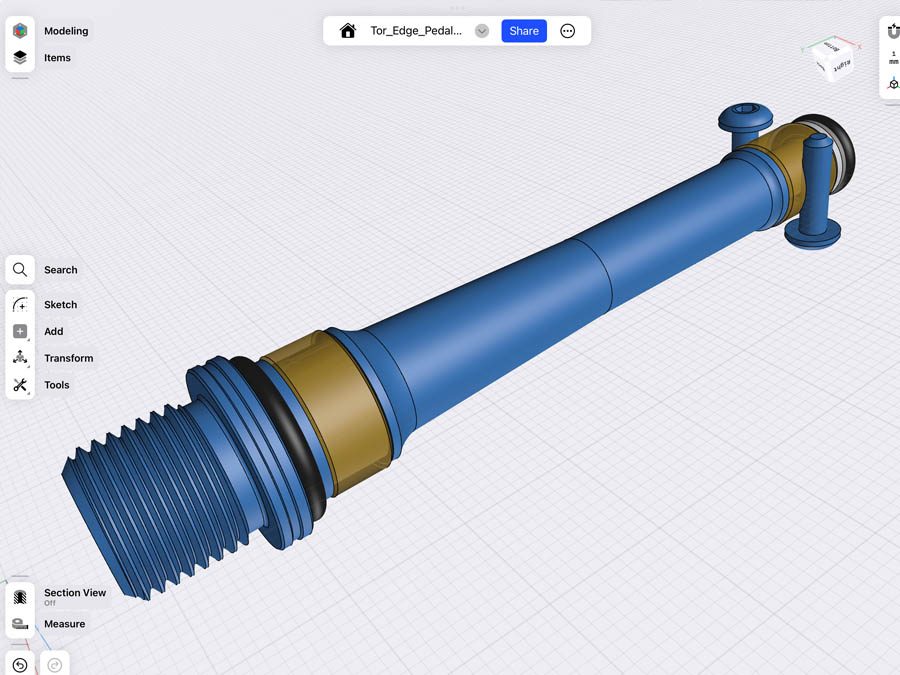

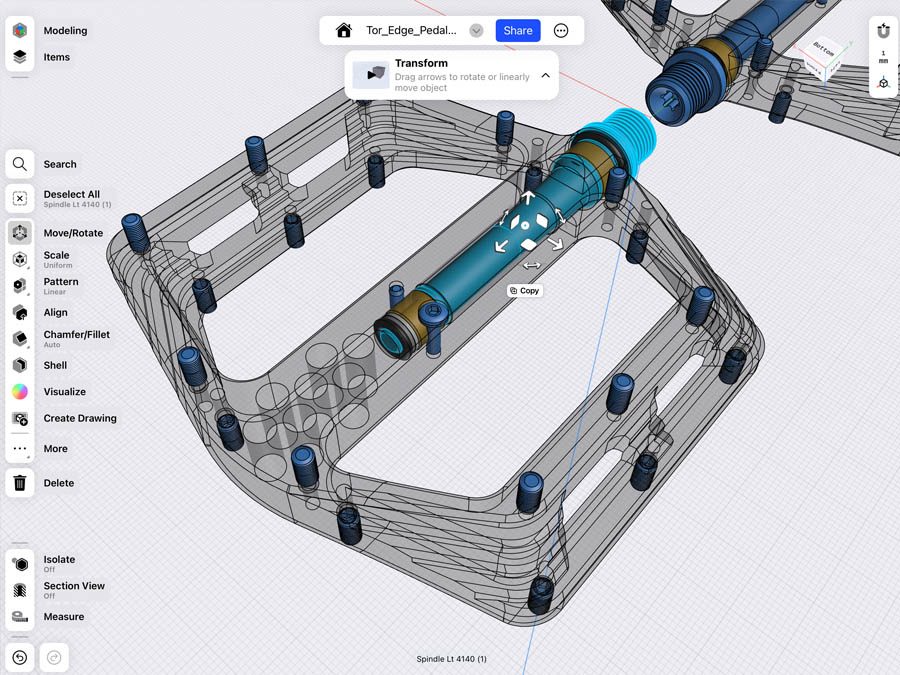

Teknika Development

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

Here are some images of the development of the cranks. Click here to see a video of a carbon 3D print